Introduction

Welcome to a deep dive into the world of Computational Fluid Dynamics (CFD), where the complexities of fluid behavior are unraveled through the power of simulation. In this post, we’ll explore the capabilities of OpenFOAM, an open-source CFD software, focusing on a particularly intriguing application: enhanced oil recovery (EOR).

EOR is a set of techniques used to extract additional oil from reservoirs beyond what’s typically achievable with conventional methods. Among these techniques, fluid injection plays a pivotal role, and that’s where our journey begins. We’ll be simulating a micromodel—a small-scale representation of a porous medium—initially saturated with oil, and then subject it to two different fluid injection strategies: water and air.

Using OpenFOAM’s robust multiphaseInterFoam solver, we will navigate through each scenario, setting the stage for a comparative analysis that not only highlights the fluid dynamics involved but also sheds light on the efficiency of each recovery method. Whether you’re a seasoned CFD analyst, a student of fluid mechanics, or simply curious about the applications of simulation in the oil and gas industry, this post promises to offer valuable insights.

So, let’s gear up to inject some science into the realm of oil recovery and witness the interplay of forces, phases, and flows through the lens of OpenFOAM.

Micromodel Setup

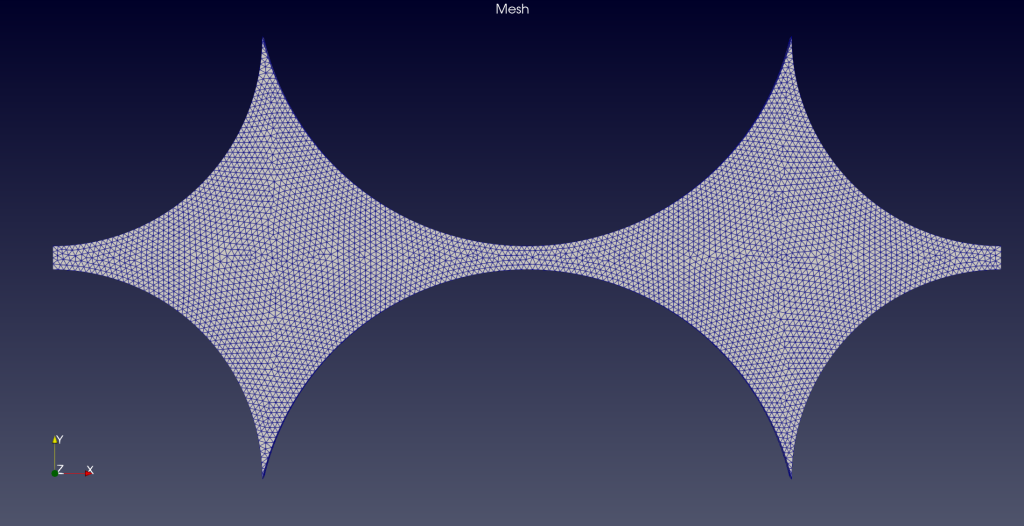

The micromodel used in our simulations is a detailed geometry that can be visualized in Figure 1. This geometry was carefully meshed using Salome to ensure precision in the simulation process and imported using IdeasUnvToFoam command. The domain is initially filled with oil, setting the stage for our investigation into the dynamics of immiscible fluid injection. The injection process is modeled with a velocity of 0.005 m/s, which is consistent across both scenarios of water and air injection. The simulations are conducted under the assumption of laminar flow, which is typical for the flow rates and viscosities involved in micromodel studies of this nature.

For the fluid properties, we have defined three distinct fluids with their respective physical characteristics. The oil in the domain is characterized by a constant viscosity model with a kinematic viscosity (ν) of 100×10−6 m²/s and a density (ρ) of 847 kg/m³. Water, our first injecting fluid, has a kinematic viscosity of 1×10−6 m²/s and a density of 1000 kg/m³. Air, the second injecting fluid, is set with a kinematic viscosity of 14.8×10−6 m²/s and a notably lower density of 1 kg/m³, reflecting its gaseous state.

The boundary conditions for the simulation are critical for accurately modeling the fluid behavior at the limits of our domain. The interfacial tension coefficients (σ) are set to 0.03 N/m for the oil-water interface and 0.07 N/m for the oil-air interface, which are values derived from empirical data relevant to the fluids in question.

The boundary conditions for the velocity (U), dynamic pressure (p_rgh), and volume fraction fields (α) for each phase are specified as it is showed in Table 1.

Table 1 – Boundary Conditions

| Field | Inlet Value/Type | Outlet Value/Type | Walls Value/Type | Front and Back Value/Type |

|---|---|---|---|---|

| Velocity (U) | Fixed Value: 0.005 m/s | Zero Gradient | Fixed Value: (0 0 0) | Fixed Value: (0 0 0) |

| Pressure (p_rgh) | Fixed Flux Pressure | Total Pressure | Fixed Flux Pressure | Fixed Flux Pressure |

| Volume Fraction (α.water) | Fixed Value: 1 | Zero Gradient | Zero Gradient | Zero Gradient |

| Volume Fraction (α.air) | Fixed Value: 1 | Zero Gradient | Zero Gradient | Zero Gradient |

| Volume Fraction (α.oil) | Fixed Value: 0 | Zero Gradient | Zero Gradient | Zero Gradient |

These boundary conditions are meticulously chosen to reflect the physical setup of the micromodel experiment and to ensure the accuracy of the simulation results. With the domain, fluid properties, and boundary conditions now clearly defined, we are well-prepared to proceed to the simulation phase and observe the fascinating fluid dynamics that unfold during the injection processes.

Simulation Scenarios

In the realm of enhanced oil recovery, the choice of injection fluid can significantly influence the efficiency and outcome of the process. In this simulation, I delve into two distinct scenarios within the micromodel environment: water injection and air injection. Each scenario is meticulously crafted to replicate conditions that are representative of real-world oil recovery operations.

Case 1: Water Injection

Water injection, a common secondary recovery technique, involves injecting water into the reservoir to displace oil and drive it towards the production wells. In our simulation, water is introduced at a controlled injection rate of 0.005 m/s, a velocity chosen to maintain laminar flow within the micromodel’s confines. The key parameters for water are its higher density (1000 kg/m³) and lower viscosity (1e-06 m²/s) compared to oil. These properties are expected to result in a more stable displacement front, as water’s viscosity contrasts with that of the resident oil, potentially leading to less fingering and more efficient oil recovery.

Case 2: Air Injection

The second scenario switches the injection fluid to air, introducing a gas drive mechanism into our micromodel. Air injection is a form of tertiary recovery, often used when water injection becomes less effective. With air’s significantly lower density (1 kg/m³) and higher viscosity (1.48e-05 m²/s) relative to water, we anticipate a different interaction with the resident oil. The expected differences include a less stable displacement due to the viscosity mismatch, leading to increased fingering and potentially less efficient oil displacement. However, the lower viscosity of air can also result in higher mobility within the reservoir, which could enhance recovery under certain conditions.

Both scenarios will be scrutinized under the same initial and boundary conditions, allowing for a direct comparison of the fluid dynamics at play. The simulations aim to highlight the contrast in flow patterns, displacement efficiency, and the overall effectiveness of each injection strategy. By understanding these key differences, we can draw conclusions about the applicability and potential outcomes of using water or air as injection fluids in enhanced oil recovery processes.

Results

The water injection scenario presented a compelling display of fluid dynamics. The simulation, illustrated in the top part of Video 1, showed that the water, with its higher density and lower viscosity, pushed through the oil-saturated micromodel with a relatively stable front. The water appears to bypass regions of oil, a phenomenon known as channeling, which can lead to less efficient oil recovery.

In contrast, the air injection simulation, showcased in the lower part of Video 1, presents a starkly different pattern. Due to the air’s lower density and slightly higher viscosity compared to water, we observe a more stable displacement front. The interface between the air and oil does not show significant fingering, a manifestation of the stable displacement.

Conclusion

The simulations for both water and air injection were executed with meticulous attention to detail, ensuring that the parameters set for the micromodel were adhered to throughout the process. The OpenFOAM environment provided a robust platform for these complex multiphase interactions, with the multiphaseInterFoam solver efficiently handling the challenges posed by the differing fluid properties. It has been an enlightening experience to explore the dynamics of enhanced oil recovery through the lens of CFD with OpenFOAM. The simulations have provided a window into the nuanced behaviors of water and air as injection fluids, offering insights into their respective efficiencies in oil displacement.

I’m grateful for your company on this journey into the intricacies of fluid dynamics within the realm of oil recovery. Thank you for dedicating your time to read and engage with this post. The enthusiasm and support from readers like you are the lifeblood of this blog. In the spirit of sharing knowledge and fostering further exploration, I have made the relevant simulation files available for download on GitHub. Feel free to utilize these resources for your own educational or project needs. And let’s not let the dialogue end here – I invite you to keep the conversation alive in the comments section below. Stay inquisitive, and happy experimenting! 🔬🚀